Services

Alternative Design Solutions and Services

McClanahan Design, at its heart, is a Product Engineering and Industrial Design firm and, as such, provides a wide range of services to achieve the end goal of a manufacturable product. But more than just services, the following is a list of our tools. We bring with us our talents, knowledge and skills to use them uniquely and effectively.

Each project is different. These services are a menu of available offerings that can be used by clients “à la carte” or as the components to a complete development project:

Mechanical Engineering

Problem Solving

Industrial Design

Computer Aided Design (CAD)

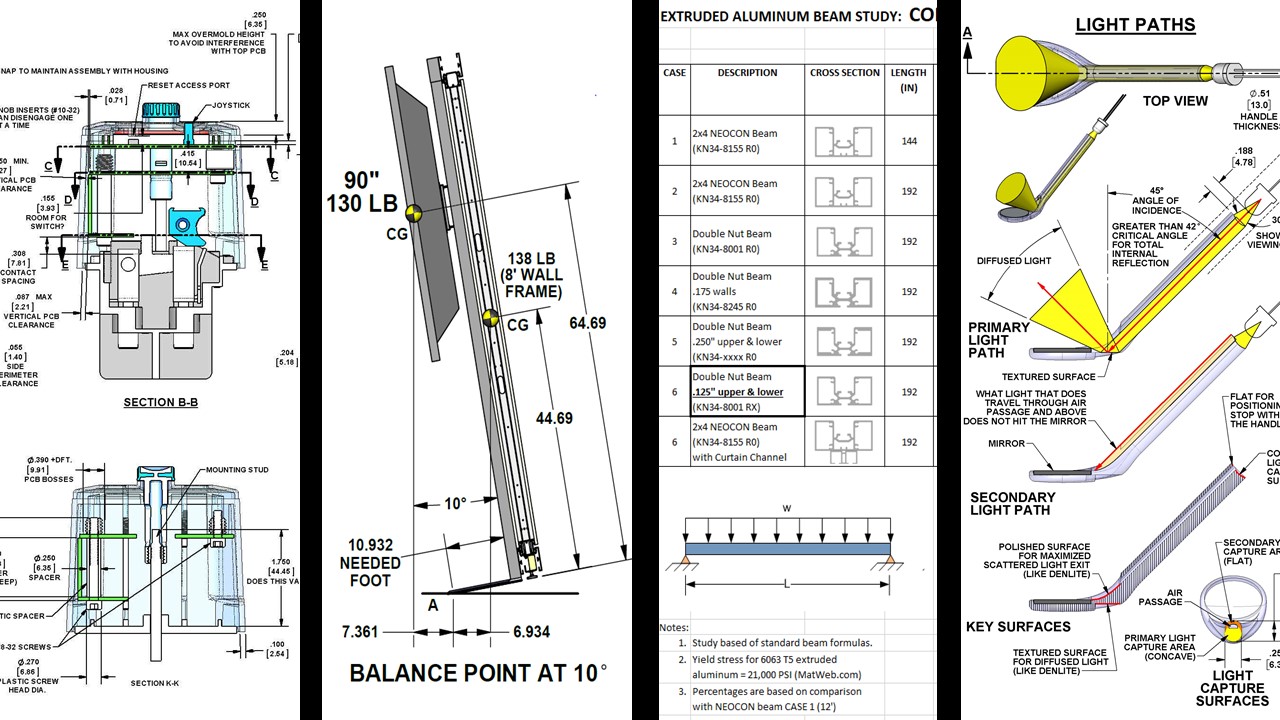

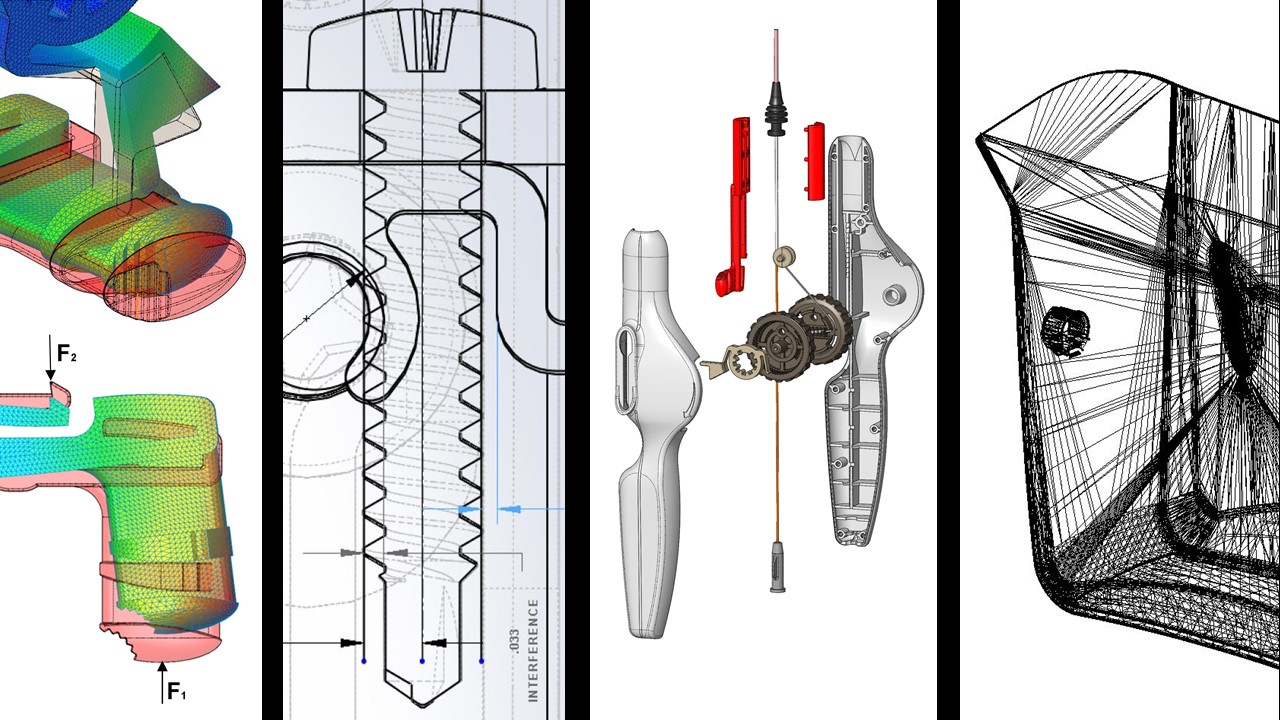

We use SolidWorks with well over 30 years of experience and can provide a broad range of capabilities including:

Communications

Frequently Asked Questions

We work with you to explore options that can make your product ideas a reality. Our Industrial Design experience and Mechanical Engineering background allows us to solve both form and function problems. Often this requires interfacing with other disciplines such as electronic designers to achieve hybrid products. We then refine and document those solution so that the product can be economically manufactured.

Our objective has been diversity. This not only helps provide a steady business environment but also provides a wide exposure to a variety of industries, materials and manufacturing processes. As a result, we are able to draw from this experience to provide the most appropriate solutions, while, of course, maintaining the confidentiality our clients expect. Through the years we have designed office furniture, children’s products (strollers, highchairs), lifts for the disabled, surgical deployment devices, dental care products, electronic packaging, travel accessories, laboratory equipment, display systems, industrial products, as well as a wide variety of other consumer products.

Regardless of the product, the design process is the same. We let you, the client, be the expert in your field and we apply our problem-solving skills to help you achieve your objective. Having an engineering background, a refined design sense and manufacturing knowledge puts us in a unique position to see that all of these aspects are considered concurrently at each phase of the design process.

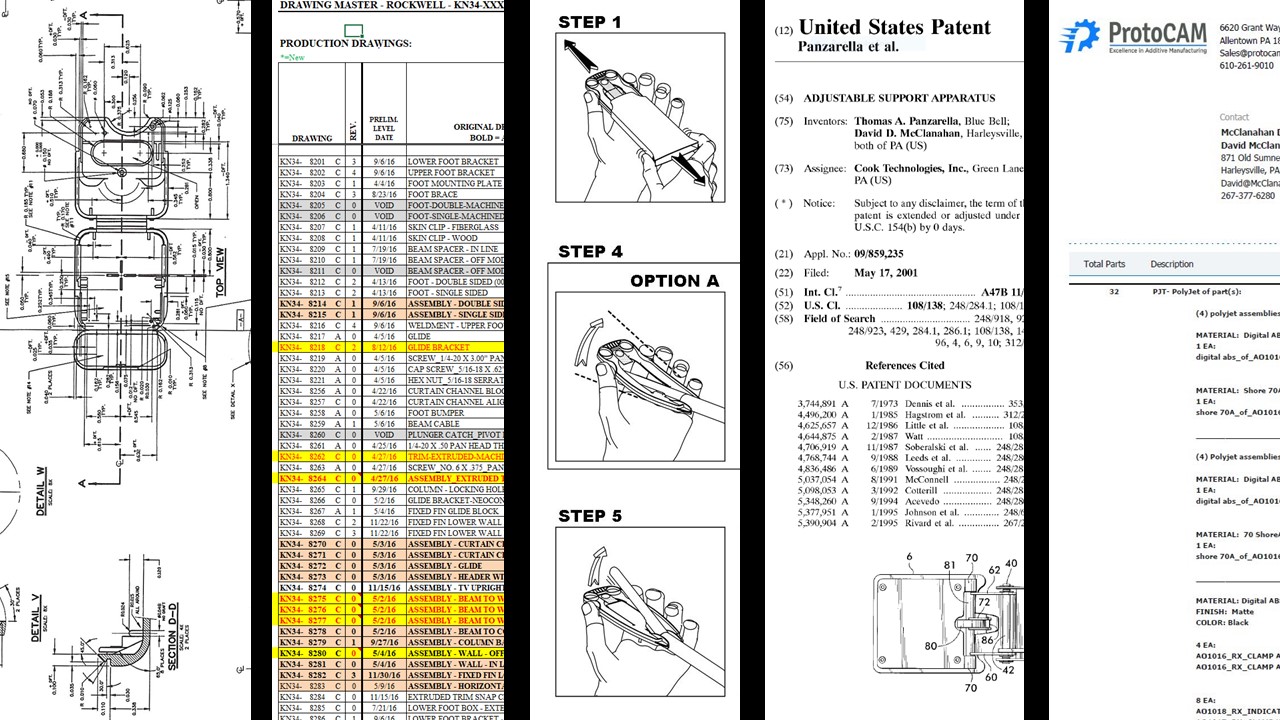

We have done this before, many times. Yet, it is not just knowing the steps that need to be performed to get a product into production, but it is having the skills to juggle the many competing demands in the endeavor. Engineering, Industrial Design, prototyping, manufacturing, marketing, distribution, sales, patents, these are all important. While we do not provide all of these services, we do have the sensitivity to each aspect and can help you carefully make decisions early on in the process to improve the odds for successfully reaching your goal.

Our goal is not to compete with your in-house staff. This is a team effort. There are several ways we can assist. At times our services are simply needed to get clients through a particularly busy period by working as if we were part of their staff. Other times, clients may just need an outside perspective on a problem or an additional team to spearhead a project. For some clients that have only intermittent product development needs, we may fill the entire design and development role so that they do not need to staff a full-time department.

Simply, whatever is most appropriate for your product. To name a few: sheet metal, tubing & wire forms, weldments, machined parts, sand & die casting, aluminum & vinyl extrusions, blow molding, rotomolding injection molding, vacuum forming, glass, wood processes, & upholstery. We are always looking at and adapting new processes and materials.

Keep in mind that this is a process of discovery and often requires multiple iteration and adaptation of the process. However, regardless of the product, the basic steps to successful results are the same.

DEFINE: The key foundation for any product design project is to define what will make the product successful. This includes function, visual appeal, ergonomics, and economic targets. You cannot get there if you do not know where you are going.

EXPLORE: Clients generally come with a basic product idea. Some have nothing more than a napkin sketch or a rough prototype but some already have patents. Regardless, there is always room for improvement. We help you consider options that can lead to a product with the best chance of meeting your objectives. There are always choices along the way and we encourage you, the client, to be an active part of this conceptual phase.

REFINE: At this phase the most promising concepts are detailed to a point that functional, structural, aesthetic and ergonomic problems can be solved, all while keeping the limitations of subsequent manufacturing in mind. While much of the work is done on the computer, this is also the time in which physical prototypes are needed.

IMPLEMENT: Ultimately the product needs to be manufactured using the appropriate material and processes to meet the economic targets. Diligence and meticulous attention to details is needed to assure the integrity of the design is maintained. Components need to be documented so that vendors can be found, costs determined and production initiated.

There are many factors that influence the cost of a project: objectives, complexity, scope, technical challenges, aesthetics, novelty, schedule, decision making. The list goes on. The important point is for us to be aware of your budget and objectives and to work efficiently to provide the best solution within those constraints. Fees are typically based on time and material. Estimates can be provided for each phase of a project based on our understanding of your needs and our experience with similar past projects. But each project is unique. Design and development is a creative process sometimes full of discoveries. Working on a time and material basis allows you the flexibility to redirect the project as you see fit. Sometimes that is deciding to pursue multiple concepts, changing your original requirements or halting development altogether. We do not like surprises any more than you and we want you to be aware of accumulative costs each step of the way. Invoices are submitted monthly rather than waiting until the end of the project.

As with cost, schedules are influenced by many factors: clear goals, timely decisions, workload, complexity, challenging issues. Let us know what your timeline is and we will evaluate what can be done to meet that objective.

Computer Aided Design (CAD) is the tool that allows us to efficiently design and document your product in virtual 3D. We use SolidWorks but there are many other CAD packages just like there are many word processing programs. Using SolidWorks, we can lay out the basic geometry, try various solutions, analyze structural properties and illustrate the results so that you understand and can actively participate in the design process. Free downloadable software will allow you to view and manipulate our CAD models as well as add your own comments and questions. These CAD models are also needed to generate the files necessary for many of today’s rapid prototyping alternatives. Later, 2D component drawings, simple outline and photorealistic illustrations can be created in SolidWorks to help communicate with investors, provide marketing images, aid in patent activities and interface with manufacturing.

No. We do have a prototype shop but this is used to build mockups of your product. Once the product is designed, vendors will need to be found to produce the actual manufactured product. We can help in this process.

We do not provide product certification. This is best done by third party laboratories or your own in-house team. During the design process we do developmental testing as part of the design process. We want to find where the product might break before we get to the end.

Give us enough information to evaluate the project: sketches, drawings, rough prototypes, design requirements. We have a simple nondisclosure agreement that can be emailed and signed if it makes you more comfortable.

Initial face-to-face meetings are always advised. If geography permits, you are encouraged to visit our office. We find that these meetings make clients more comfortable and greatly improve communications throughout the project.

Based on what you have given us, we will provide an estimate that lays out a preliminary schedule and anticipated associated costs for the early phases. Later phases can be discussed but greatly depend on results of earlier phases.

Sign our standard contract which outlines important aspect of our relationship. New clients may be asked to provide a partial payment advance which will be applied to the final bill.

The project then begins.